Why Businesses Fail

An Organizational Perspective

Tom Rand

Consultant, USA

Introduction

Businesses fail because management does not have effective control of the business. To believe otherwise is to believe that the chief executive officers of five major computer manufacturing corporations engineered their own terminations earlier this decade.1 No doubt there were many other managers with far less marketable products forced to resign in the interim. Management is too far removed from revenue-producing processes. The interval between the time a revenue plan is launched and the time the actual revenue is collected is, to all intents and purposes, a black hole into which human resources are poured with no mechanism to measure their effectiveness. Visibility is nonexistent or, at best, extremely limited.

Visibility is the capability to see and understand what is going on within the business. Stated another way, visibility is the capability to see and to understand the condition of the revenue-producing process as the revenue plan unfolds. The condition of the process is determined by the product's position in the supply chain relative to the actual demand, i.e., the process is in good condition if the product and all of its components can be moved from their location in the process through the balance of the process in time to meet the date the product is scheduled to be shipped. Visibility is also the capability to see and understand how effective employees are when they position products in the supply chain relative to demand. In other words, visibility is the capability to see the impact on decisions and activities that employees are having on the revenue-producing process at the time that decisions are made and the activities occur.

Information comprehensive enough to provide, daily, a composite view of the production process and a view of the employees' decisions and their activity does not exist. Information that could be made to measure effectiveness has instead been broken up into meaningless bits of unrelated data and distributed among dozens of people and departments. Information broken into bits of disassociated data limits visibility to information conveyed by bits of data from which it is not possible to make well-informed decisions or to take timely action. Information broken into unrelated bits of data breaks up what would otherwise be a coherent communication pattern from which the organization could learn the characteristics of the process and, over time, by accumulating information and forming mental histograms, learn the characteristics that are unique to the organization and to the business. Fragmented information limits the acquisition and accumulation of knowledge necessary to understand, manage, and control the business. In addition to the information process, the revenue-producing process is also fragmented, which further limits visibility.

THE REVENUE-PRODUCING PROCESS

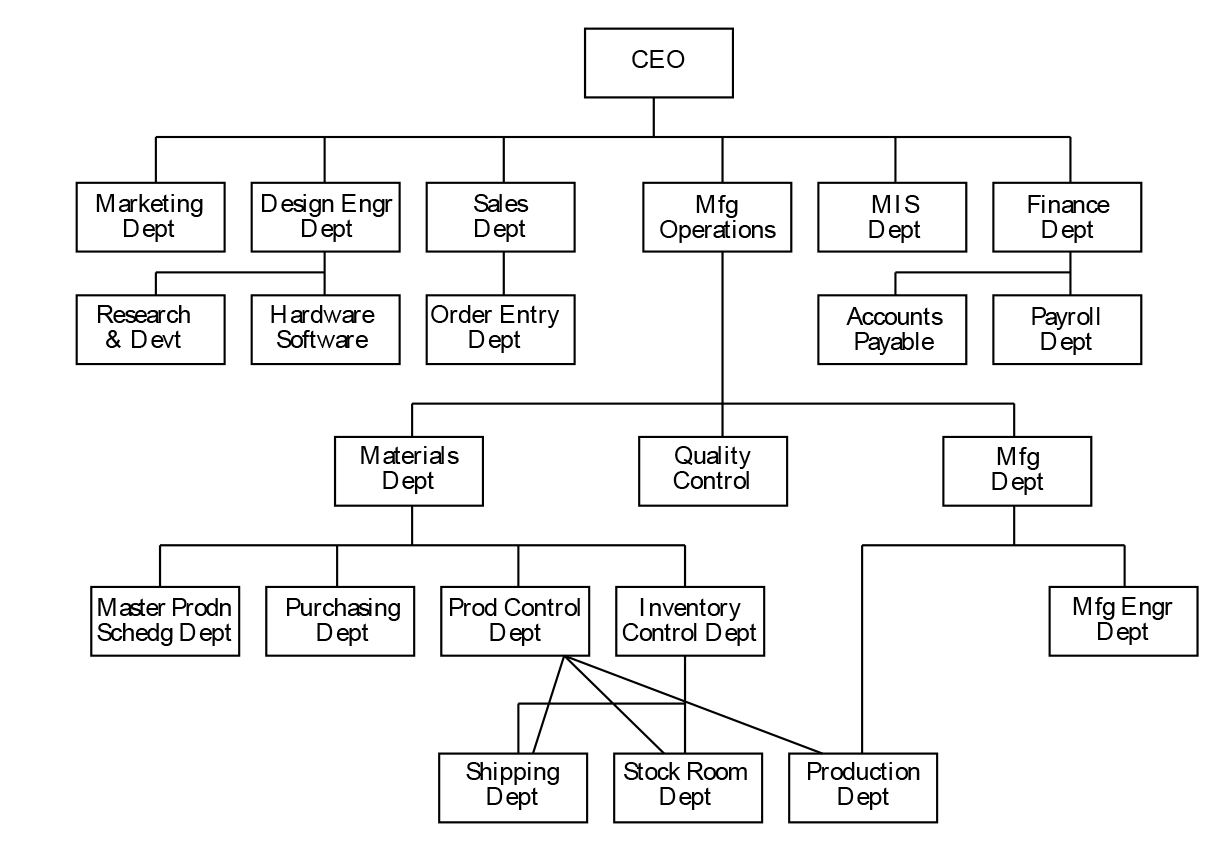

The revenue-producing process extends from the time a customer's order is received to the time the order is shipped. The product should flow from one end of the process to the other in a coherent, continuous flow. The process is, instead, broken up into dissociated operations. Responsibility for these operations is allocated to several people who work in different departments. An organizational chart typical of many manufacturing companies is shown in Figure 1. Each box indicates a department. The drop-shadowed departments indicate the areas where material is physically located in the factory.

Figure 1

In Figure 1, the inventory control department is responsible for managing materials located in the stockroom. The stockroom is where the products' parts are stored and prepared for assembly. Preparation of the parts for assembly consists of pulling parts from their location in the stockroom and putting them into a “kit.” The production department is responsible for assembly of the product. This department assembles the parts issued in the kit and transfers the assembled product to the shipping department. The production control department is responsible for scheduling material out of the stockroom, through the production department, and through the shipping department. Thus, responsibility for three of the steps in the production process—namely kitting, assembly, and shipping—are divided among several people who work in three different departments. There are additional steps in the revenue-producing process that are shown in Figure 2.

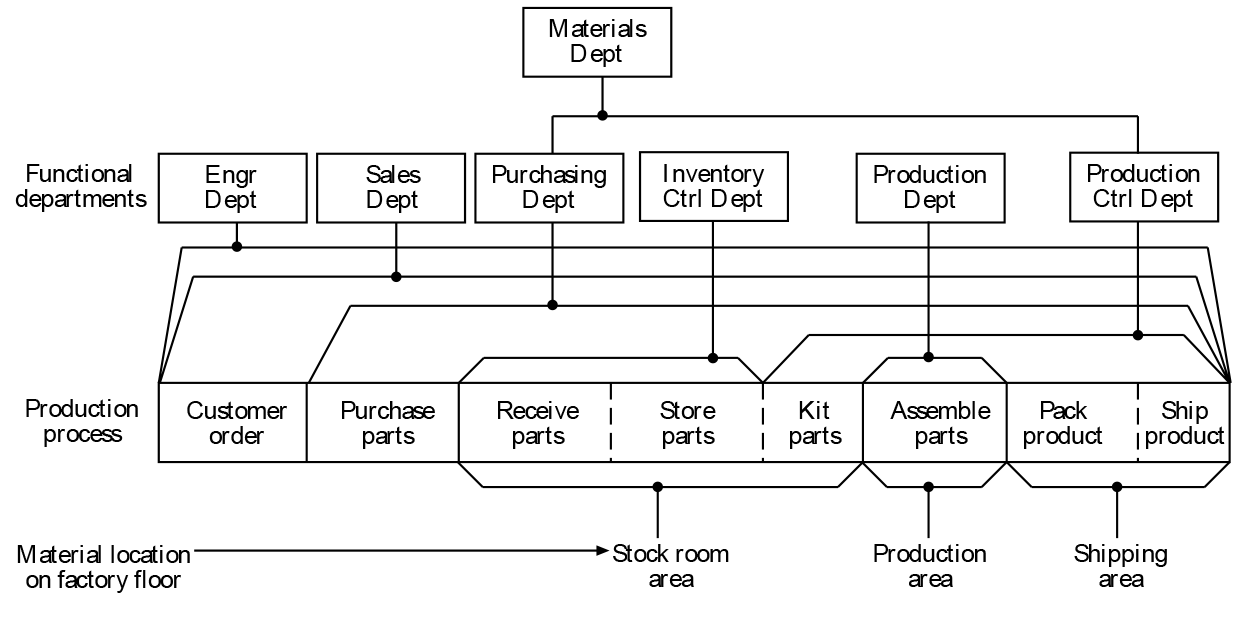

Figure 2 Revenue-producing process

In Figure 2, the row labeled “functional departments” describes what function each department performs. The dots linking the departments to the horizontal lines describe the impact that the decisions and activity that occur in each department have on the production process. This arrangement of departments and operations disperses responsibility for the use of resources and the effectiveness of the production process throughout the manufacturing operations department. There are other departments outside of the manufacturing operations department, such as marketing, finance, quality, design engineering, and sales, the latter two of which are shown in Figure 2, whose decisions and activity, directly or indirectly, also affect the production process. Thus, responsibility for the effectiveness of the production process is distributed throughout the corporation. Overlapping departmental responsibility for pieces of a fragmented production process and uncontrolled interdepartmental activity mean that, as they say, “if everybody is responsible, nobody is responsible.” The horizontal lines extending from each department to the steps in the production process not only indicate overlapping responsibility, they can be thought of as lines of communication that make up a communication pattern. With few exceptions, such as formal engineering design changes, communication between and among people and departments is unmanaged. In no case are communication patterns, i.e., information processes, documented in a manner that reflects the impact of decisions and activity and the resultant condition of the production process. The origin, destination, and integrity of information are largely unknown. Different departments act on different pieces of information obtained at different times and no one has a composite picture of the condition of the global production process.

Overlapping responsibilities are like overlapping shingles. They obstruct visibility down into the interior of a structure and out to its exterior. In companies so structured, management cannot see into the interior of the organizational structure to see who is accountable for the effectiveness, or the lack thereof, of the revenue-producing processes. Just as rain on a roof readily flows to adjacent shingles, accountability within the organizational structure readily flows to adjacent departments. Organizations so structured are breeding grounds for incompetence. Where incompetence exists, the lack of accountability and successful efforts to sustain revenue flow will keep it hidden form management's view. The lack of visibility due to fragmented information processes, production processes, and functional departments is designed into the organizational structures of virtually every company in every supply chain. Thus, visibility between and among companies in the supply chain is also severely limited.

SPECIALIZATION

The structure of the organization is designed with departments who depend on, and are dependent on, each other. Departments equipped with only the knowledge required to perform their specialized functions do not contain the global knowledge required to improve conditions for the whole organization. Even if they did, no single department has the autonomy or the authority to impose change on the others. A condition of limited visibility, shared responsibility, and minimal accountability is literally designed into the organization. In the absence of visibility, no one can see, nor does anyone have the incentive to see or to curtail, the unproductive use of human and material resources that occurs in many businesses every day. Ineffective performance is an integral part of the organization. Virtually everyone acknowledges the need to change unproductive conditions and there is no short age of intelligent people to implement change. Yet somehow conditions never change for the better. There is a mechanism working to prevent change. A clue to the nature of this mechanism lies in the nature of specialization.

Specialization requires that many people in many disciplines work together in what we call an “organization.” We adopt our place in the organization and take responsibility for the job we are hired to do, but nobody takes responsibility to insure that the revenue-producing process is working effectively. There is no mechanism put in place by management to insure that the revenue plan is executed in an effective manner. In other words, there is no mechanism to insure that the labor of employees is directed effectively. However, there is a mechanism that does direct employee activity. During the planning interval, the revenue plan is changed countless times for countless reasons, such as an incorrect forecast or changes made by customers, to name just a couple. These changes are unplanned and occur as circumstances dictate. There is, as a result, a mechanism that consists of the interrelationships between and among all of the personnel in the supply chain that extends from, but is not bounded by, all of the corporation's suppliers, the people and departments within the corporation itself, and all of its customers.

All of these entities make up the industrial machine. Left as they are to their own propensities, these interrelationships and the resultant activity are driven by unplanned, uncontrolled circumstance rather than by any well-reasoned, manageable plan. It is this mechanism of circumstance that directs employee activity and preempts control of the corporation's human and material resources. In other words, management's failure to develop and implement a mechanism to direct employee activity in an effective manner is to cede responsibility and control of the employees' activity to a mechanism of circumstance. Thus, a mechanism of circumstance assumes control of the company's human and material resources. As a result, much of what employees do in organizations so structured—insofar as management does not have the visibility to direct labor to the best advantage—is labor unconsciously directed by circumstance. Instead of management running the business, the business begins to run management. It is only the redundant efforts of experienced, knowledgeable employees and the valiant efforts of recruits naïve enough to believe that they can make a difference that mean that the outcome is anywhere near favorable. Specialization has left a void in our capability to think in terms of global systems required to manage constantly changing conditions. It also plays a role in the maintenance of this mechanism.

The evolution of specialization has honed our minds and focused our vision on the detailed, tangible, technical problems of immediate concern. While specialization is a key component of productivity, the sum of the knowledge required to perform all of the detailed activities does not add up to the wisdom required to perceive the uncontrolled global condition that is a result of that activity. Specialization has limited our ability to perceive the impact, adverse or otherwise, on the performance of the organization. Opportunities to improve conditions are hidden beyond the bounds of our technical intellect and myopic vision.

One could forcefully argue that wisdom has long since been bred out of our species. In any event, it is this mechanism of uncontrolled circumstance generated by the sum of uncontrolled activity that directs much of the day-to-day activity in our corporations, not management. Management, made up of specialists, is not equipped with the range of knowledge or understanding required to manage changing circumstances, much less to predict and adapt to those changes that are pending. In effect, specialization has painted us into an intellectual corner. Management can only react to circumstances as circumstances materialize. As such, much of management could be dispensed with and the business would still thrive. Oligopoly or deep pockets will carry the day until the machine forces a change of management, owners, or, in severe cases, bankruptcy.

In addition to oligopoly and deep pockets, the machine thrives on the enthusiasm, initiative, and energy of naïve recruits, which it dissipates over time by its regimen of compliance, conformity, and consensus. Recruits with visions of a prestigious career in manufacturing provide a source of renewed vitality, but consigned to a life of menial labor are soon burned out and learn what their more experienced predecessors have learned. They learn that they can do no more than do their jobs and eventually resign to do no more than their jobs. We all become the proverbial cogs in the machine. Employee burnout, high turnover, unqualified employees, inefficiencies, excessive costs, and mandatory overtime are all debilitating conditions that contribute to a surreptitious state of decline, the rate of which is determined in part by the degree to which indifference and ineffectual activity prevail.

This is not to say that all companies are disagreeable places to work; quite the contrary. Professional managers can maintain a pleasant working environment even with a traditional organizational structure. We may enjoy our work, feel productive and, perhaps, even feel appreciated. However, these vicarious comforts only serve to obscure further the presence of an ineffective mechanism with the illusion of security in an alien environment until the economic performance of the company deteriorates. The economic reality of ineffectual labor is that after a decade or two of practice, many people will be forced into a market with ordinary skills whose equilibrium is readily satisfied by recruits with smaller pecuniary appetites. Thus, experienced knowledgeable specialists enabled by genuine camaraderie, mutual trust, and their acquired understanding of the mechanism are gradually displaced and replaced with less experienced, less knowledgeable, less expensive employees.

Age-nic cleansing is only one of many forces behind the decline of the company's intellectual capital. Specialization, the explosive growth of technology, competition, shorter product life, and diminishing margins have placed a heavy demand on inexperienced specialists who over time have come to rely on emulation, habit, and tradition rather than intellect. The demand for people to supply the insatiable demands of uncontrolled activity and growth has moved inexperienced, myopic specialists up in the managerial ranks with the rising tides of technology into positions of responsibility far above and beyond the scope of their specialties and comprehension. Inexperienced specialists in turn hire generations of less experienced, less knowledgeable specialists, all of whom become blameless casualties of this declining intellectual stratum. Our collective intellect, perception, and insight have been gradually diminished by the myopic requirements of our environment. Today, the activity required to run our production processes no longer demands much in the way of wisdom and contemplation. Primitive systems require only rudimentary labor to sustain them. The daily activity typical of many manufacturing organizations will bear this out.

ANALYSIS

The typical manufacturing organization finds itself on the verge of failure virtually every day. Missing parts or parts that are out of position in the process are identified by stockroom or assembly employees when they discover that the parts are not located where they were supposed to be. As stated earlier, visibility is limited. That is, the condition of the process is not visible to management or employees ostensibly responsible for the performance of the process. The cause of the stockout, which may be attributable to one or all of the reasons described below, and the potential delay of revenue are also invisible. Further, the cause is irrelevant. Action is focused only on activity that will sustain the flow of revenue. It is this circumstance that dictates activity, not management. Personnel in the purchasing, materials, production control, and production departments must determine the status of parts required to meet the revenue plan, i.e., they must look up the quantities and the locations in the process, a myriad of parts, for a myriad of products, in a myriad of database files to determine the condition of the revenueproducing process, all of which is done by all concerned in a redundant manner.

What employees who work throughout the supply chain are doing is extracting bits of data about each part of each product from a database so that they can piece together a composite picture of the condition of the revenue-producing process at the eleventh hour to prepare for a daily production meeting. The effect of this preparation is to make it appear that the condition of the revenue-production process is known to those ostensibly responsible for the effectiveness of the production process. In the process of composing this composite picture of the process, other problems attributed to an inadequate supply of parts may be uncovered. These problems will be presented to management at the daily production meeting as “challenges” that will be overcome during the course of the day's activity. Management, satisfied that the day's revenue goals will be met, remains content with the illusion of process knowledge and control, while the underlying cause of these challenges remains invisible. Thus, the redundant “analysis” of the revenue-producing process and the subsequent redundant activity will be repeated the following day and every day thereafter.

The word “analysis” is routinely used to sum up this act of preparation for the daily production meeting. It, as does this brief article, falls far short of describing the servile work and the debilitating organizational psyche it produces. Analysis implies a type of intellectual logic applied to acquire a deeper understanding of some system or mechanism. The level of understanding achieved by this act of preparation for the production meeting is limited to an understanding of what parts and their priorities in terms of revenue to focus activity on today. No understanding of the mechanism that caused the shortage of parts occurs. A deeper understanding of the mechanism would facilitate a solution to the cause of the part shortage and thus eliminate the reason for such ineffectual labor.

The word analysis also implies a contemplative act of inquiry to facilitate some improvement. This act of preparation is dictated by circumstance, not management. It must be performed as circumstance dictates, immediately. There is neither the time nor any requirement for contemplation and, in fact, preparation for a daily production meeting requires little more than the capability to endure the daily tedium of mindless, repetitive drudge work. Confined to the limits of this work, the genetic code of this specialty evolved and generations of blameless bureaucrats are bred to achieve only this minimum level of understanding and competence. One can see by this example how activity can limit the development of the intellect. The result of this evolution and perpetual act of preparation in no way improves the dysfunctional system. It only serves to obscure, sustain, and institutionalize it. The epidemic of this mindless ineffectual labor so described does not end with the end of the production meeting. There are still challenges to be overcome.

After the meeting, the participants scurry off to interrupt and enlist the aid of what would otherwise be thoughtful productive employees to help do more mindless, ineffectual work expediting parts, who in turn interrupt still other employees to coordinate their activity in an effort to appropriately reposition parts in the supply chain to insure that the challenges are overcome so that the revenue for the day will be forthcoming. I am using the example of a parts shortage to illustrate how one seemingly small element in the process triggers a large amount of ineffectual activity in the manufacturing operations department. Similar labor is expended to rectify aberrations in work orders, sales orders, engineering change orders, and every other element and in every department in the process that requires control. Aberrations in all of these seemingly dissociated elements and departments cause employees to react in concert and severally to readjust these elements to make the global process work. The fact that these elements are largely uncontrolled, as is the resultant activity, keeps employees in a constant of reaction to circumstance which, to the degree that they are successful, provides the illusion of control.

Add to these daily charades mangement's incompetence and the resulting sabotage of the revenue-producing process in the form of poor product designs, inaccurate product documentation, inadequate production tools, defective parts, defective production processes, purposeless paperwork, and the passive acceptance of adverse supplier decisions at the front end of every process, as well as the imposition of contrary customer demands at the end of every process for every company in the supply chain, and the resultant waste of human resources reaches colossal proportions. The problems caused by these conditions are routinely relieved by the successful efforts of employees to sustain revenues, while the underlying causes and costs of these problems remain hidden from view. Profits are a crude measure of effectiveness.

EFFECTIVE LABOR

The effectiveness of labor in a well-managed company may be as high as the proportion of effective labor to total labor, where ineffective labor consisting of benign placeholders is a benign expense. In companies where incompetent management prevails, the proportion of what would otherwise be effective labor is substantially reduced by the extent to which incompetence facilitates ineffective labor in sabotaging the revenue-producing process. That is to say, the effectiveness of what would otherwise be effective labor is reduced by the extent to which ineffective labor is allowed to become a physical and psychological burden upon effective revenue-producing labor.

Consider that the global supply chain is much longer than the supplier and the customer adjacent to the subject company described above. Consider further that the supply chain consists of dozens of companies, some of which have thousands or tens of thousands of employees. Consider still further that there are hundreds of thousands of products, each of which has a supply chain of various lengths linked at various junctures along the chain by specialized relationships. Now consider that all of these companies have more or less the same dysfunctional organizational structure, and you have a machine that literally wastes tens of thousands of people's lives and their intellectual potential. Management constrained within the functional bounds of a specialized box in the functional hierarchy does not have the visibility, the knowledge, or the authority to change these conditions. The art and science of manufacturing and management have not and cannot—with existing organizational structures driven by externally prescribed circumstance and uncontrolled activity—progress beyond this primitive level.

NOBODY HAS CONTROL OF THE MACHINE

Management, by ceding control of its resources to a mechanism of circumstance, consign employees to a life of reaction to the circumstance of uncontrolled activity and growth, which precludes the possibility of learning, which in turn adds a decline of the company's intellectual capital to its list of handicaps. There is, except within the specialty of new product development, little or no premium placed on the ability to think. Organizations on the verge of failure avoid it by habitual effort that maintains the conditions that brought them to the verge. The course of action has been set by circumstance. What needs to be done has been preordained. It is easier and wiser to go along and do things that can be immediately done, albeit with a large tolerance for frustration, rather than to propose improvements that cannot. Such proposals raise questions of competence, and there is little incentive to risk political repercussions that will add the discomfort of disfavor to the discomfort of frustration. Only action that will overcome the challenge of the moment is appropriate. Dissent, doubt, even indifference is forbidden by the machine's regimen of consensus and conformity. We can do little more than go along to get along.

Thus, the surreptitious decline of the business is concealed by feigned felicity and the laudatory posture of sycophants and fervent, albeit naïve, team players alike. Meanwhile, employees continue to react to circumstance caused by the unplanned, uncontrolled activity of other people in the supply chain over whom they have no control. Perpetual reaction to current events perpetually limits the sphere of our thinking and our activity to the present. The day, the days that follow, and the future are preordained. There is neither the time nor the opportunity to understand how the mechanism works. Any mechanism that cannot be understood cannot be controlled. Few people have control of their future and fewer still have control of their jobs. Nobody has control of the machine. We are all its unconscious subjects and its complex, all-pervasive mechanism can be neither seen nor understood. The machine has grown beyond the control of the engineers responsible for its evolution.

The engineers,2 over the course of time and evolving technologies, have implemented dysfunctional organizational structures in the undirected piecemeal fashion of specialization. That is, they have implemented structures consisting of fragmented, specialized functionaries, all of whom are driven in the same general direc

tion but as individual functionaries have no conscious sense of direction. Financiers, professors, consultants, and other like-minded thinkers are, for all their visionary acumen, unable to see through the mists of time and tradition, much less through the ever-increasing size and complexity of dysfunctional organizational structures. This lack of visibility not only obscures the lessons of the past, it obscures the possibilities for the future, which, if realized, would open new frontiers and opportunities for learning and real security for all concerned.

We are in effect suspended in time by habit and tradition. Management, unconscious of the absence of any mechanism to reveal the presence of the machine, is rendered powerless to effect change. Under these conditions, there is no hope of improvement for the better. Thus, there has been the evolution and surreptitious growth of a machine that, in the absence of visibility, has captured control of the business and of our lives. We readily adapt to its benevolent cadence and march down the road to mediocrity and failure in spite of innumerable lessons from the past. Existing organizational structures are anachronistic machines that will gradually wear down and eventually bring down even the most powerful corporations and their leaders. No one has effective control of our corporations. Herein lies one reason that businesses fail.

ACHIEVING EFFECTIVE CONTROL

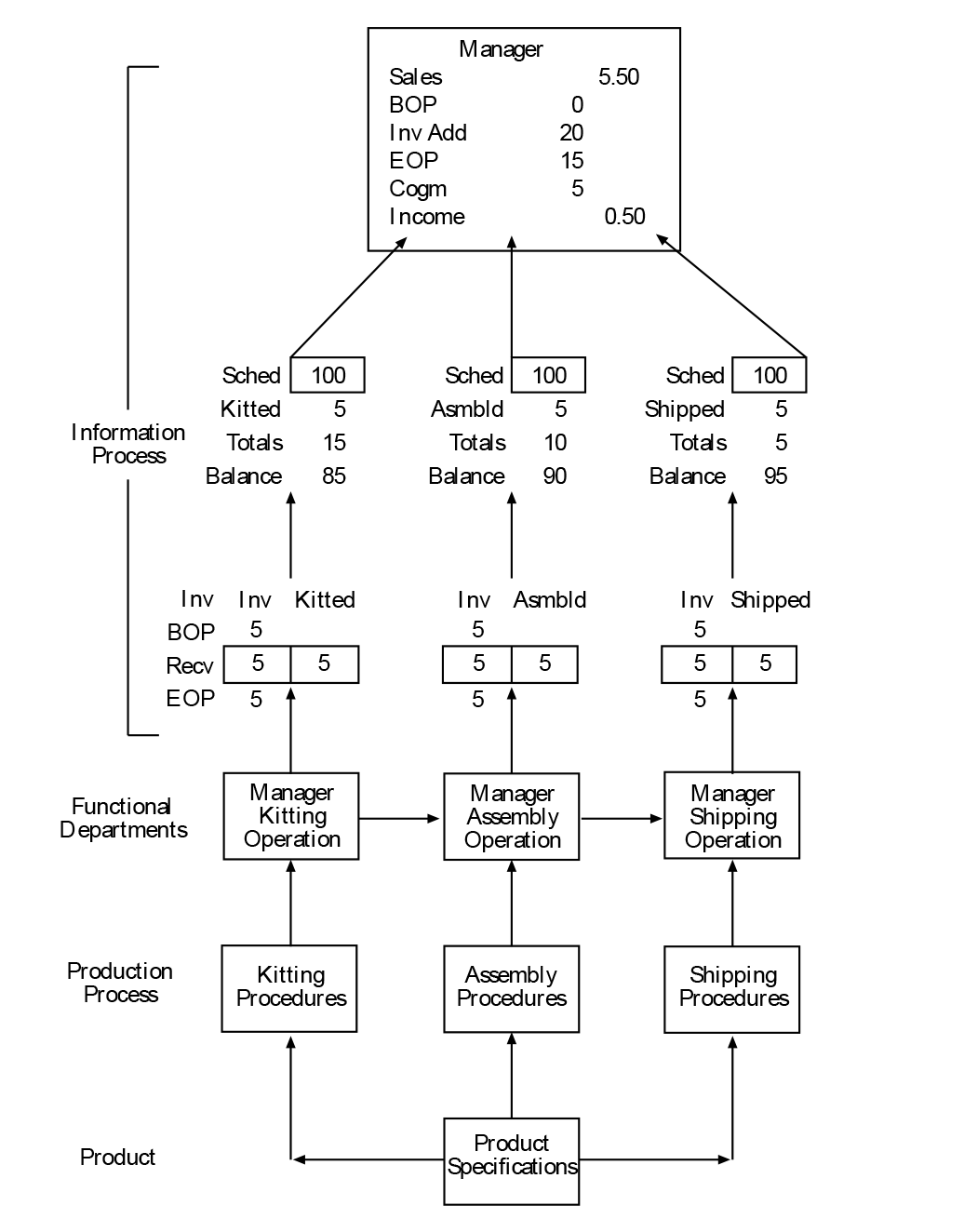

What can be done to achieve effective control of the business? An organizational structure with its structural elements properly aligned is shown in Figure 3.

Figure 3 An organizational structure with its elements properly aligned

The production process consists of three discrete steps or operations; namely, “kitting,” “assembly,” and “shipping.” These operations and their sequence are dictated by the need for a physical location in which to position material next to each other to facilitate an efficient production sequence or “flow.” The purpose of the first step is to temporarily store and prepare the parts for assembly. This is called a “kitting” operation. The purpose of the second step, “assembly,” is to assemble the parts to make the product suitable for sale. The purpose of the third step, “shipping,” is to make the product suitable for transport to the customer. The operating details within each operation have as their origin the products' specifications, i.e., the quantity and the cost of materials, labor costs, tools, and the factory's capacity are documented in the process procedures. The other five operations shown in Figure 2 will be assimilated by the employees responsible for the kitting, assembly, and shipping operations, as described below.

One key feature of this organizational structure is that the purpose of each element and the relationship between and among the elements are visible.

There is a one-to-one correspondence between the elements in the organization, which consist of the information process, the functional departments, and the production process. This one-to-one correspondence eliminates the fragmentation and misalignment of information, departments, and processes described earlier. Every element in the organization has a value-added purpose. Every element produces a product for which there is a customer. That is, the value of each element is such that if it were removed, the process, when optimized, would cease to function.

The purpose of the procedures is threefold: to document how the process and the other elements in the structure work, to provide planning criteria for all the employees, and to provide them with a knowledge of the product and the process required to control and manage the process effectively. The purpose of the production process is self-evident: to produce a product suitable for sale to a customer. The purpose of the functional departments is to produce a product for which there is a “customer,” the customer being the subsequent department in the supply chain. This is a change in the contemporary mindset that views people as capable of nothing more than pushing parts through a process that they can neither understand nor control. The purpose of the information process is to provide management with an aperture through which to see the condition of the revenue-production process. Management and employees will see, daily, a composite picture of the revenue-producing process in terms of the revenues, products, parts, costs, and the precise position of products and parts in the process. In short, the purpose of the information process is to provide management with the visibility required to get effective control of the business.

Learning is a second key feature of this organizational structure. Three elements in the process of learning are planning, execution, and measuring results. The mechanism of specialization has dissected these elements of learning and allocated them to different departments in the organization; namely, the materials, production, and accounting departments. Dissecting the elements of learning into three separate functions prevents people from learning anything beyond the limited sphere of their mental and physical activity. The fragmented learning process is the origin of organizational psychoses. Neither the people nor the organization can achieve an effective sense of an organized, coherent purpose.

In the new structure, these functions have been decentralized and made an integral part of each of the revenue-producing departments. Each department is now an autonomous business unit equipped with the elements of learning that enable it to learn how to effectively produce a product for which there is a customer. Each of these three departments is equipped with the resources required to manage its own customer backlog, the planning resources required to meet the backlog, the information resources required to execute the plan effectively, and the accounting resources required to measure its own results.

It is the capability to plan, execute, and measure results that makes each department an autonomous, self-sustaining business unit. Decentralization also provides each department with the autonomy that is necessary to make improvements. Making improvements will require employees to think and learn how to become successful businesspeople. As autonomous managers, they can learn how their internal mechanisms work and further concentrate the elements of learning—planning, execution, and measurement—into the sphere of each individual's mental and physical activity, thus reducing to one job what it currently takes two or three people to do. In this way, employees responsible for the effective performance of the revenue-producing process can assimilate responsibility for the other five operations shown in Figure 3. In managerial terms this is called “job enrichment.”

This new mindset treats employees as if they are capable of thinking and creative problem solving. Companies that adopt this mindset will have employees who are capable of thinking and creative problem solving.3 The increase in the proportion of effective labor will be substantially more than the reduction in the proportion of ineffective labor, as will be shown below.

Another key feature of this organizational structure is that the communication pattern is visible to all concerned. The origin, the content, and the destination of the information necessary to keep everyone appraised of the condition of the process are clearly documented and visible to all concerned. The numerical relationships between and among all of the elements in the organization are clearly visible. Relational information flows up the organization. The capstone of the information process is the income statement, whose content, because it is visible to all, flows down the organization. The income statement is also management's “home page.”

The performance of each manager is visible to upper management via the documented visible links. The links extend down into each operation to the product's component level, where quantities, costs, and their precise position in the process are visible. For example, there is a one-to-one relationship between the numerical content of the information and the physical product. That is, for each quantity of “five” shown in the “end of period” row (EOP) in Figure 3, there will be a quantity of five products physically located in a designated location in the process. The designated locations of the parts for the product and a description of the parts have been omitted to keep the model as easy to understand as possible. These documented visible links keep management and employees alike informed as to the daily condition of the revenue-producing process as the revenue plan unfolds. Thus management, hitherto running blind, now has very acute visibility.

Information presented in this comprehensive format will provide management, employees, suppliers, and customers, in concert and severally, with the prescient visibility required to see what needs to be done, and what can and cannot be done, and thus to control and effectively direct resources to keep revenue plans on track during the planning interval. Thus, ineffectual labor and the millions of dollars of superfluous overhead normally required to bring derailed revenue plans back on course will no longer be necessary. Multiple products can be managed with a similar comprehensive information format, with links from the “home page” to different products and their respective income statements and revenue-producing processes. New markets, new products, and new production processes will require the development of new lower-level, component-level information and product structures. Thinking, creativity, and decisions will have to occur in a timely manner at the lowest levels in the organization.

A new genus of organizational architects will evolve. Generalists, free of the myopic nature of specialization, will out of necessity learn to develop the mechanisms required to direct, integrate, and measure the results of organizational behavior at all levels in the organization. The need to think both globally and in terms of the details that make up the global landscape will develop individual and collective intellects, which in turn will increase the intellectual capital of the company. People, given the environment and this opportunity for self-improvement, will strive on their own volition to achieve self actualization.4 That is, they will seek to do what they are best fitted to do and thus perform at their highest possible potential. Management will be free to lead a selfdirected organization, as opposed to pushing an immovable bureaucracy.

Under conditions so described, effective labor will increase by an absolute minimum to an increasing portion of the total labor as the proportion of ineffective labor decreases. This increase in effective labor only accounts for the physical capability of the human resources. The large number of human minds largely confined to mindless tasks is an immense source of untapped productive potential. Releasing this latent innate intellectual capability will enable labor to generate value of incalculable proportions in the spirit and fashion of entrepreneurs.

CONCLUSION

In order to gain effective control of the business, management must implement a mechanism to control it. Information processes, production processes, and functional departments must be aligned to make the relationship between and among these elements in the organizational structure clearly visible. The relational organizational structure will provide managers at all levels with the visibility required to see the condition of their revenue-producing processes. The pulse of the process, universally observable, will insure its economic health.

When control of the business has been achieved, the same techniques must be adapted to the organizations of its suppliers and customers. In this way management can extend its now acute visibility beyond the immediate bounds of the company throughout the industrial supply chain. The sphere of its communication pattern, knowledge, and intellectual capital will expand accordingly.

The communication pattern, while it appears to be static by virtue of its format fixed on paper, is in reality a dynamic management tool. The content of the information changes as conditions vary. Patterns will emerge when these changes are viewed consistently over a period of time. These patterns are a reflection of the decisions and activities of suppliers, company employees, and customers that occur as conditions vary. Information patterns are reflections of behavior patterns. When these patterns have been assimilated, behavior can be anticipated and resources can be allocated to the best advantage.

By developing an acute sense of prescience, the intellectual capital of the organization is further developed. Higher levels of understanding will provide management with the visibility to bring the mechanism of circumstance into even sharper focus and attain greater control of the business. When other companies in the supply chain change their organizational structures to the new model, visibility between and among companies in the supply chain will become increasingly more acute. Thus businesses working jointly and severally will make up a coordinated enterprise throughout the supply chain and over time acquire an everincreasing amount of control over the industrial machine.

When we have visibility—that is, the capability to see and to understand how the mechanism works—we will have mastered the machine. We will have regained sufficient control of our jobs to make our day, and the days that follow, and, eventually, the wisdom to see beyond the horizon and open up new frontiers in which to make our future. Then and only then will we have effective control of the business. Then and only then will we have identified, isolated, and removed one of the reasons that businesses fail.

NOTES

- San Jose Mercury, June 19, 1993: 10D. The subject computer companies are Apple, IBM, Digital Equipment, Hewlett-Packard, and Compaq.

- For detailed information on the role of the engineer in industry, see Veblin and Thorstein (1947) The Engineers and the Price System, New York: Viking Press.

- The Golden Book of Management (AMACOM, 1984: 462-3) provides an overview of Douglas McGregor's two theories of the universe, Theory X and Theory Y.

- See Abraham H. Maslow (1970) Motivation and Personality, New York, Harper & Row: 46.